Industrial printing trends to watch for in 2023

7 industrial printing trends for 2023

The industrial printing industry is evolving with several trends to watch for in 2023, including digital printing, customization, sustainability, printing on new substrates, layer by layer technologies, and printed electronics. External factors, such as economic and social developments, also influence the industry.

1. Digital Printing

Digital printing is expected to account for 21% of printed products by 2024, up from 17% in 2019. This growth is due to the increasing popularity of digital printing for its ability to produce high-quality prints quickly and efficiently, as well as the rise of e-commerce and print on demand services. (Source: The Future of Digital vs Offset Printing to 2024, market report by Smithers)

2. Customization and Personalization

There is a trend towards customization in the industry, with companies offering more personalized products and services to meet the specific needs of their customers. Variable data printing is also a growing trend, allowing for the efficient production of personalized products using digital printing and a single template

3. Sustainability

The printing industry is becoming more conscious of its environmental impact, leading to a trend towards the use of eco-friendly materials, production methods, such as water-based inks and energy-efficient printing equipment. There is also a trend towards the use of biodegradable and compostable materials in packaging that are more sustainable and have a lower impact on the environment

4. Printing on New Substrates

The demand to print on non-paper materials, such as glass, textiles, metal, plastic and specialized packaging materials, is growing. As the technology improves, businesses will benefit from efficiency and customization on countless new coated materials, including layered paper and PVC

5. Layer by Layer Printing Technologies

3D printing and InkJet printing are gaining popularity as they create objects or images by adding material layer by layer. InkJet printing is used in industrial manufacturing to print conductive materials and other functional materials onto various substrates. 3D printing, also known as additive manufacturing, enables the production of complex and customized products on demand with minimal waste and lead times

6. Printed Electronics

This growing field allows for the printing of electronic components, such as pathways, antennas and batteries, onto various substrates, leading to the creation of flexible and low-cost electronic devices. It is increasingly being used in wearable devices and smart packaging. The technology is also being used in the production of large-scale systems like solar panels

7. External Factors

The industrial printing industry is influenced by a range of external factors, including economic, political, and social factors. For example, the COVID-19 had a significant impact on the industry, with a shift towards the production of personal protective equipment and materials. Similarly, geopolitical situation, the war in Ukraine, are driving the development of new products and technologies

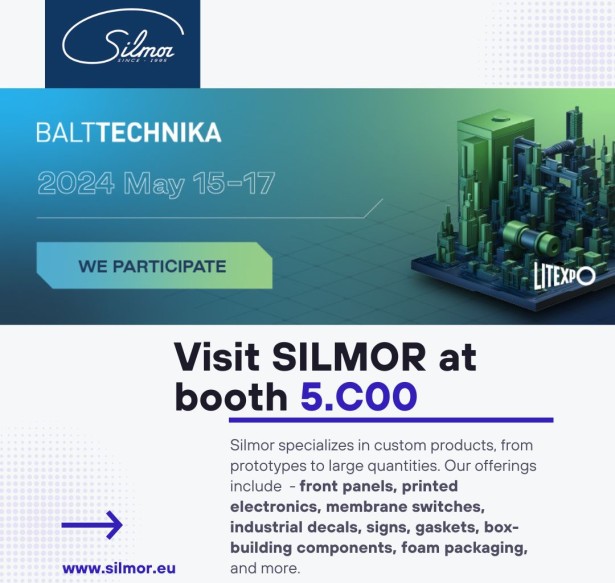

To conclude, SILMOR industrial marking is always innovating and improving. SILMOR industrial marking is always innovating and improving. We as a leading industrial printing company in the Baltics, have embraced several trends in the industry. These include expertise in printed electronics, digital printing equipment, variable data printing for personalization, and the ability to print on new substrates. The company has also adopted eco-friendly production methods and is continuously investing in R&D to improve products and services.

Contact: sales@silmor.eu to learn more about how we can help your business succeed in the coming year.