Guide to Choosing the Right Surface Labeling Solution

Variety of surface labeling solutions

With a variety of options available, including laser engraved plates, Metalphoto, screen printed overlays, RFID tags, and laminated vinyl labels, it’s important to select the solution that best suits your specific requirements. In this comprehensive guide, we will explore these surface labeling solutions and provide valuable insights to help you make an informed decision.

Laser Engraved Plastic or Metal Plates

Laser Engraved Plastic or Metal Plates: Ideal for applications requiring durability, laser engraving provides precise and permanent markings. It allows for intricate designs, variable data, and 2D barcodes. Consider laser marking for high-quality, long-lasting, and easily readable markings.

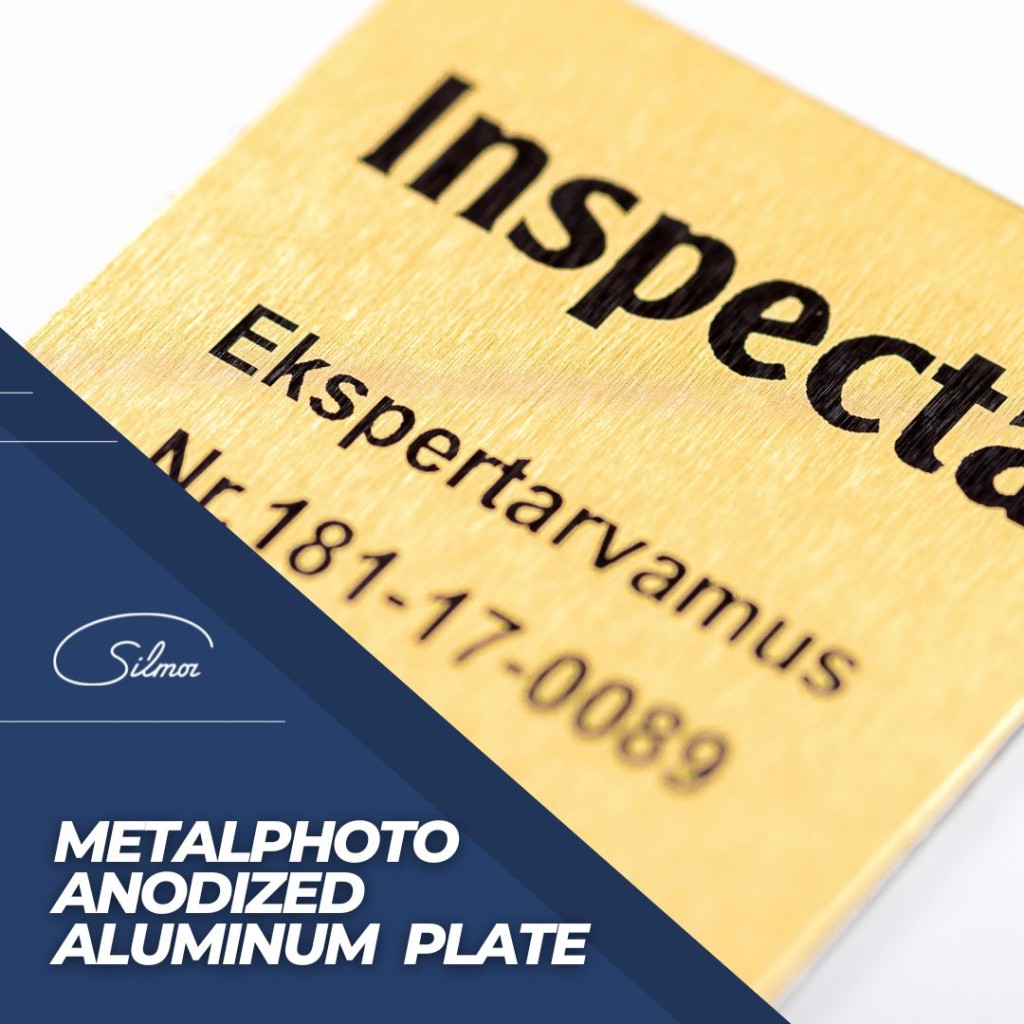

Metalphoto Plates

Metalphoto Plates: Utilizing a photosensitive process, Metalphoto plates offer durability and resistance to harsh environments, chemicals, and UV exposure. They are commonly used for robust identification, serial numbers, or product specifications.

Screen Printed or UV Printed Plastic Overlays

Screen Printed or UV Printed Plastic Overlays: These overlays, created through screen printing or UV printing techniques, allow for customization with graphics, text, and icons. They provide durability and resistance to abrasion, chemicals, and UV exposure, making them suitable for control panels, equipment labeling, and branding purposes.

RFID Tags

The printing industry is becoming more conscious of its environmental impact, leading to a trend towards RFID Tags: RFID technology utilizes radio waves to capture and read data stored on tags. It enables real-time tracking, inventory management, and anti-counterfeiting capabilities. RFID tags are valuable for applications requiring advanced traceability, such as supply chain management, asset tracking, and access control.

Laminated Vinyl Labels

The Laminated Vinyl Labels: Cost-effective and versatile, laminated vinyl labels can be printed with variable information, graphics, and barcodes. They offer resistance to moisture, UV exposure, and chemicals, making them suitable for product labeling, warning signs, and more.

Choose the best attachment solution

When it comes to attaching plates, consider options like adhesive backing for simplicity and versatility, mechanical fasteners for secure attachment, or magnetic backing for easy and non-permanent placement. Choose the attachment method based on surface material, desired permanence, and ease of installation.

Making informed decisions for surface labeling solutions

Evaluate Costs v.s, longevity: Consider the durability, readability, and longevity of the markings when evaluating the costs of marking solution. Based on longevity needs and exposure environment it is smart to look for the marking that fits those requirements and there is no replacement needed in the lifespan of your project.

Seeking expert advice and support is highly recommended. Consult professionals or trusted suppliers with experience in different marking technologies. They can guide you based on your specific requirements and help you select the most suitable surface labeling solutions.

Contact: contact@silmor.eu to learn more about how we can help you to choose the right solution.